His three research lines are constructed using both numerical and experimental methods, up to high TRL levels (e.g., pilot-scale):

Highly cited articles:

Kanyilmaz A, Demir A.G., Chierici M., Berto F., Gardner L., Kandukuri S.Y., Kassabian P., Kinoshita T., Laurenti A., Paoletti I., Plessis A., Razavi J., Role of metal 3D printing to increase quality and resource-efficiency in the construction sector, Additive Manufacturing, Volume 50, 2022, 102541, ISSN 2214-8604, https://doi.org/10.1016/j.addma.2021.102541

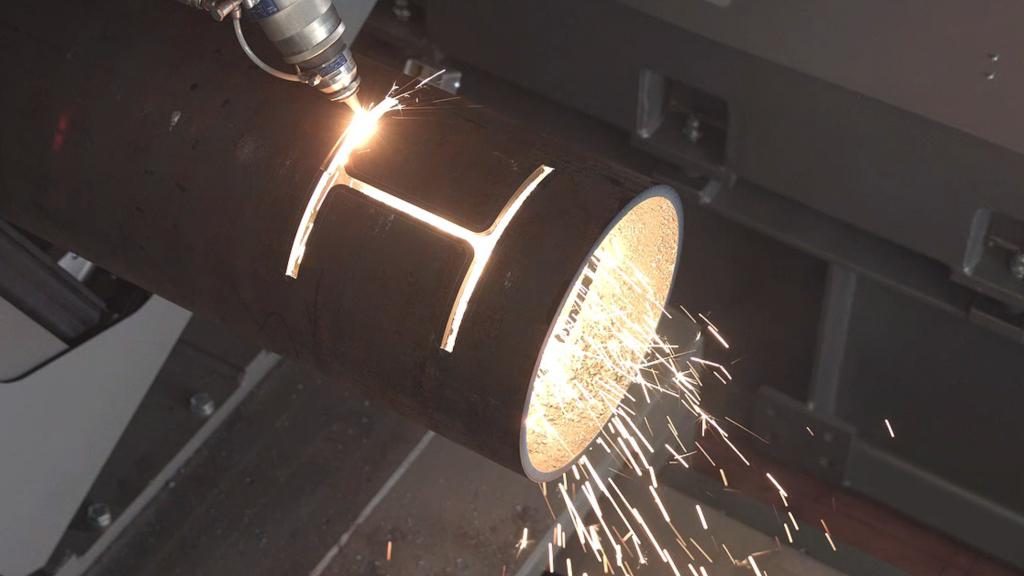

Kanyilmaz, A., The problematic nature of steel hollow section joint fabrication, and a remedy using laser cutting technology: A review of research, applications, opportunities, Engineering Structures, v. 183, 2019, p. 1027-1048, ISSN 0141-0296, https://doi.org/10.1016/j.engstruct.2018.12.080

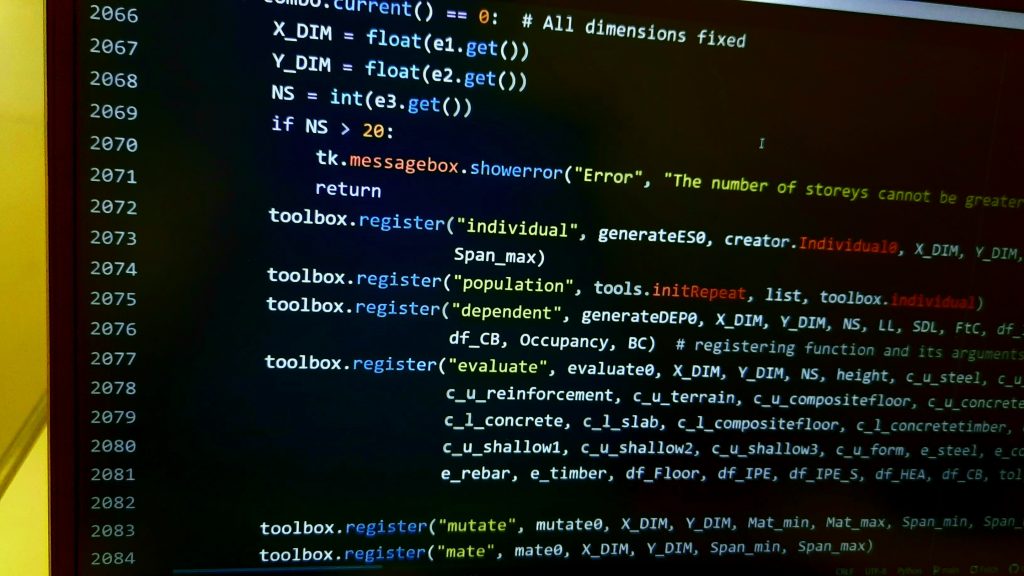

Kanyilmaz A., Tichell P.R.N., Loiacono D., A genetic algorithm tool for conceptual structural design with cost and embodied carbon optimization (2022) Engineering Applications of Artificial Intelligence, 112, art. no. 104711, https://doi.org/10.1016/j.engappai.2022.104711

Kanyilmaz A., Dang V., Kondratenko A., How does conceptual design impact the cost and carbon footprint of structures?, Structures, Volume 58, 2023, https://doi.org/10.1016/j.istruc.2023.105102.

Kanyilmaz, A., Birhane, M., Fishwick, R., Castillo C.. Reuse of Steel in the Construction Industry: Challenges and Opportunities. Int J Steel Struct (2023). https://doi.org/10.1007/s13296-023-00778-4.

Menghini A., Kanyilmaz A., Calado L., Castiglioni C.A., Experimental Assessment of the Behavior of Tubular Truss Girder Joints Fabricated with Laser Cutting Technology (2023) Journal of Structural Engineering (United States), 149 (6), https://doi.org/10.1061/JSENDH.STENG-12019