Biography

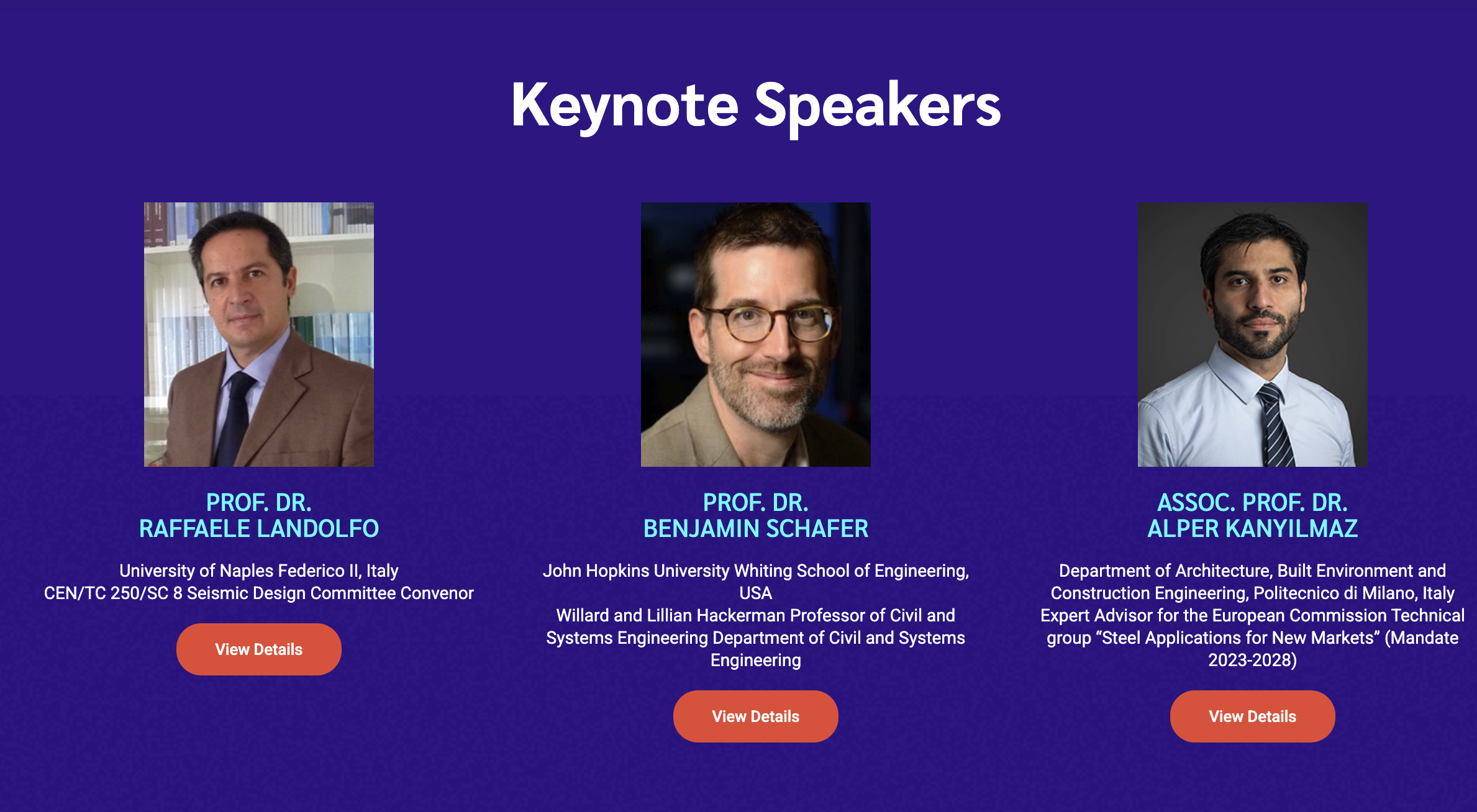

Alper Kanyilmaz is an associate professor in the Department of Architecture, Built Environment and Construction Engineering of Politecnico di Milano in Italy. He works at the intersection of mechanics, data science, and digital technologies to deliver a safe and resilient built environment, studying how structures behave and age across their life cycle and how their dynamic response can be measured and interpreted. His research integrates structural engineering with signal processing and computational modelling (in collaboration with metrology and computer science experts), spanning nonlinear dynamic analysis, inverse problems, laboratory and full-scale testing, and data-driven methods for diagnosis, prediction, and multi-objective optimization.

Recently, he has built a new line of research that dual-purposes existing telecom fiber-optic networks as vibration sensors in structures. His vision is to give structures the ability to "speak" through the infrastructure that already connects them, transforming cities from passive built environments into active, self-monitoring structural observatories. His team has shown through laboratory tests that standard active telecom fibers can capture vibration signatures comparable to reference sensors, an idea that led to a Marie Skłodowska-Curie Postdoctoral Fellowship, a patent filing, and growing interest from both telecom and structural engineering communities.

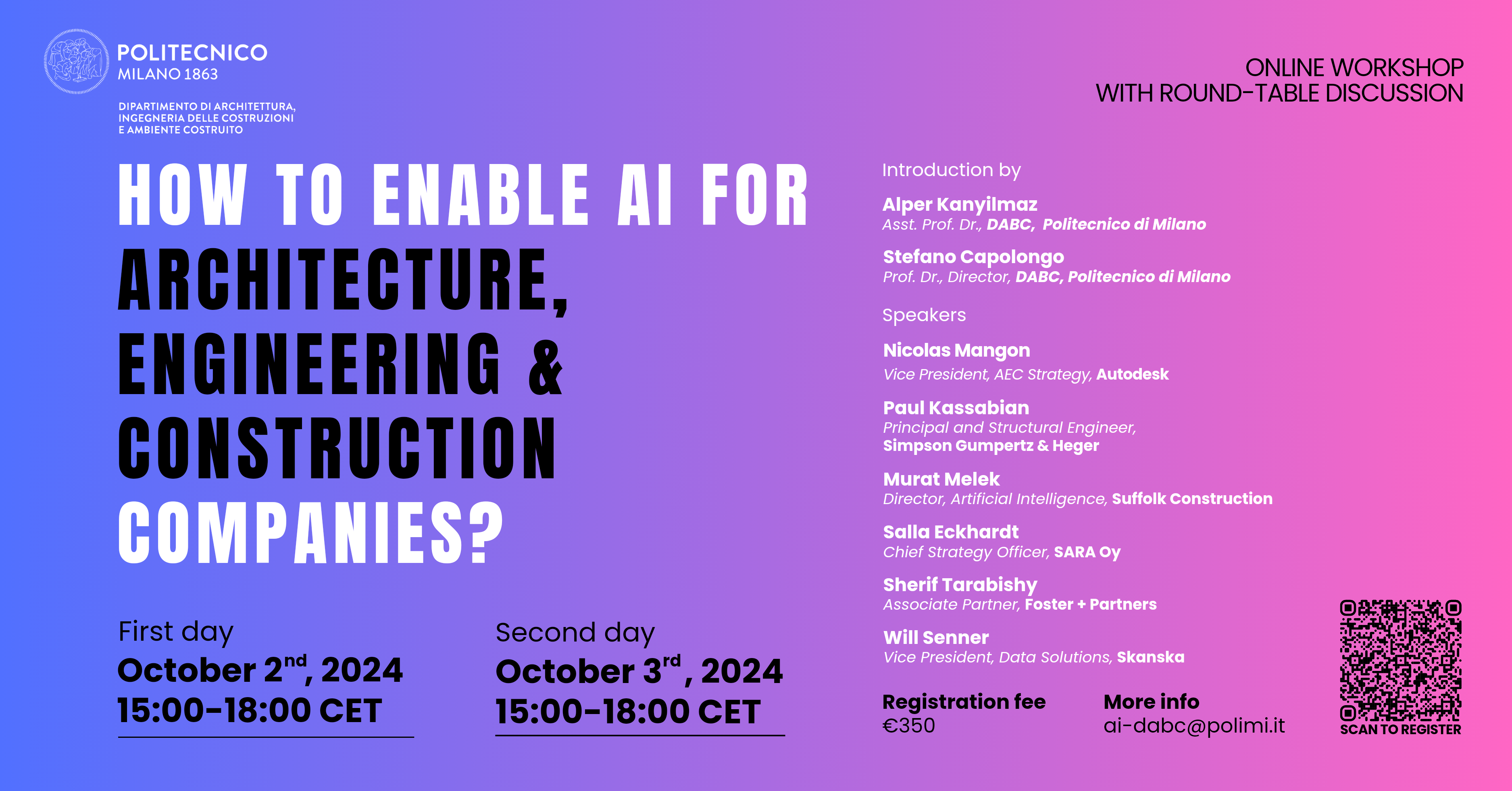

He has been the principal investigator of multiple EU-funded projects (including ConstructAdd and LASTTS, which he coordinates) with a combined budget exceeding €14 million and over 40 international partners. He applies data-driven approaches, artificial intelligence, and advanced manufacturing techniques to drive a digitalized and sustainable transition in the Architecture, Engineering, and Construction sector towards life-cycle driven building structures. He is an Expert Advisor for the European Commission Steel Advisory Group (SAG, Mandate 2025–2029) focused on the R&D domain of steel construction applications, and a project monitoring expert for European Commission, B.1 (Future Low Emission Industries). He teaches structural mechanics and life-cycle driven structural design to more than two hundred students per year (with consistent student evaluations between 3.4 and 3.8 out of 4.0), and advises industry and public bodies on digital construction and disaster-prevention strategies through MSc and PhD thesis supervision and direct consultancy.

Full article list / Books / Talks

If you would like to cooperate, please contact him.

Research

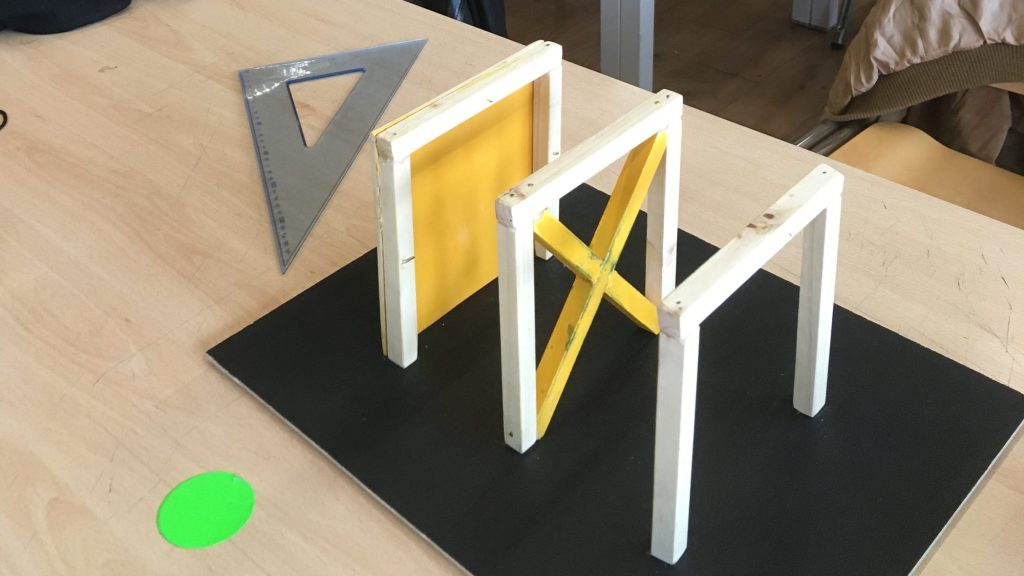

His three research lines are constructed using both numerical and experimental methods, up to high TRL levels (e.g., pilot-scale):

Highly cited articles:

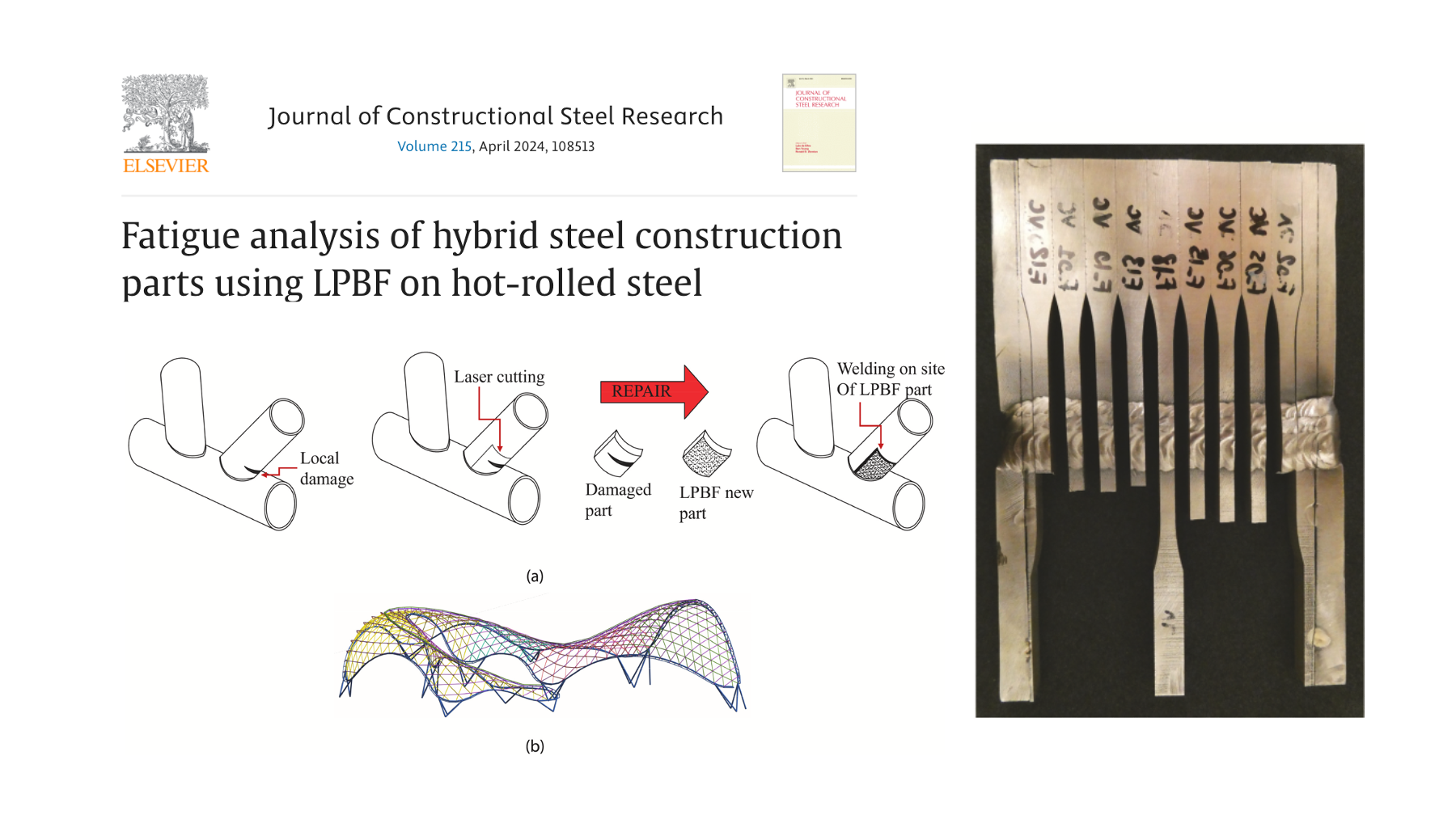

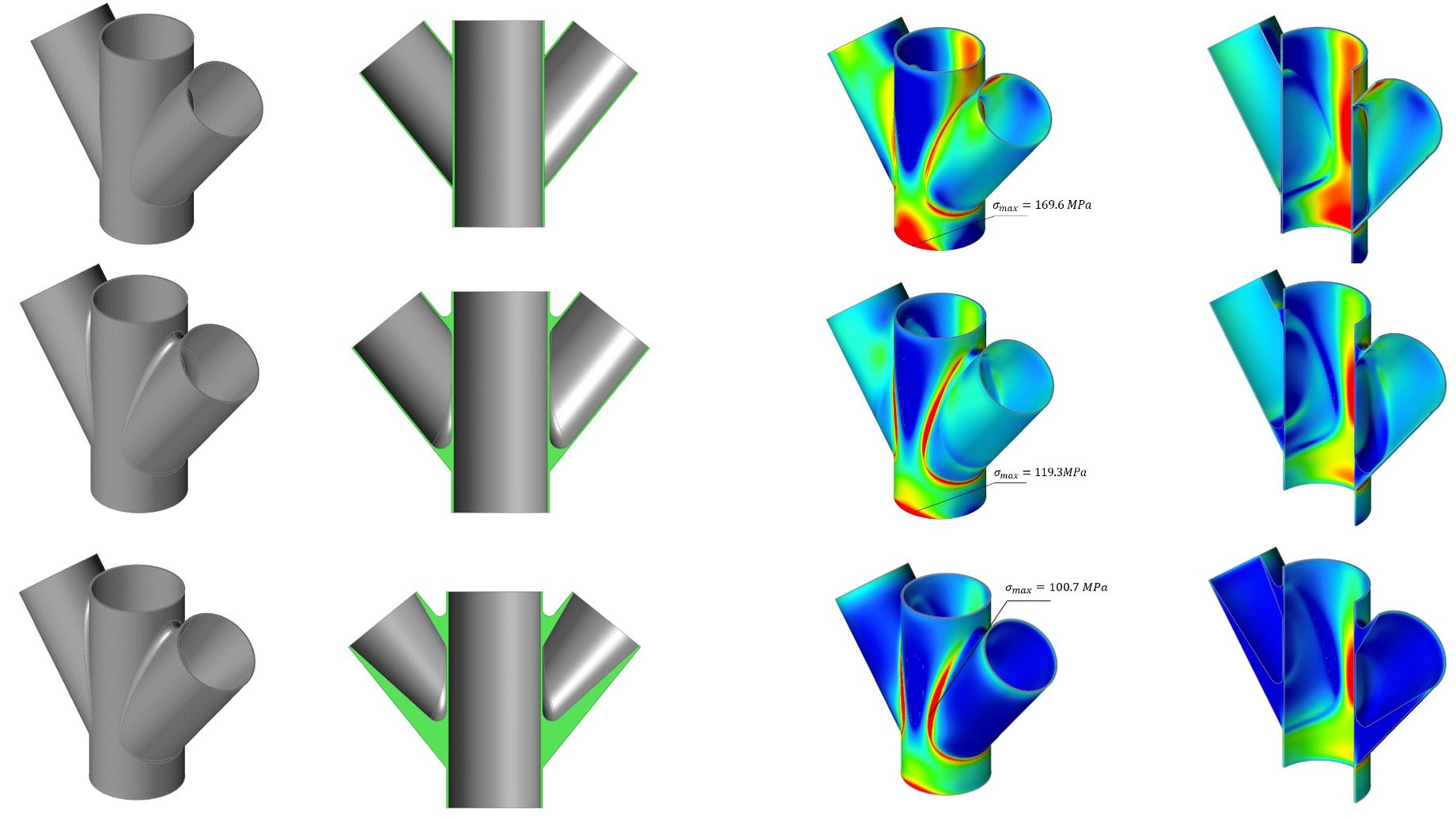

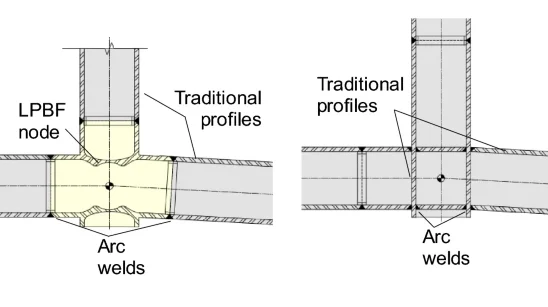

Kanyilmaz A, Demir A.G., Chierici M., Berto F., Gardner L., Kandukuri S.Y., Kassabian P., Kinoshita T., Laurenti A., Paoletti I., Plessis A., Razavi J., Role of metal 3D printing to increase quality and resource-efficiency in the construction sector, Additive Manufacturing, Volume 50, 2022, 102541, ISSN 2214-8604, https://doi.org/10.1016/j.addma.2021.102541

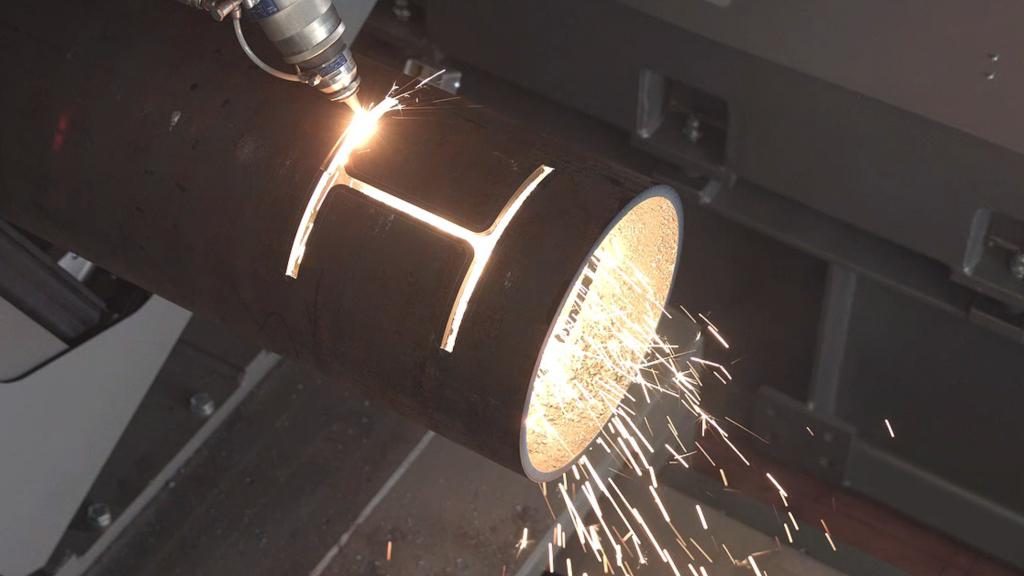

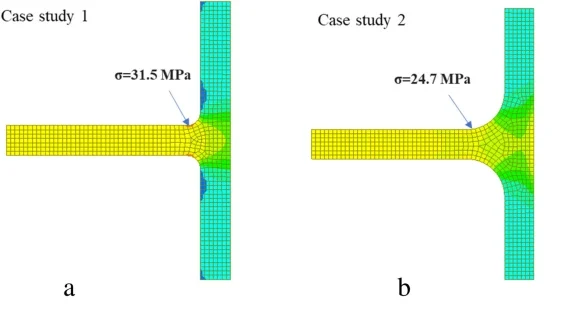

Kanyilmaz, A., The problematic nature of steel hollow section joint fabrication, and a remedy using laser cutting technology: A review of research, applications, opportunities, Engineering Structures, v. 183, 2019, p. 1027-1048, ISSN 0141-0296, https://doi.org/10.1016/j.engstruct.2018.12.080

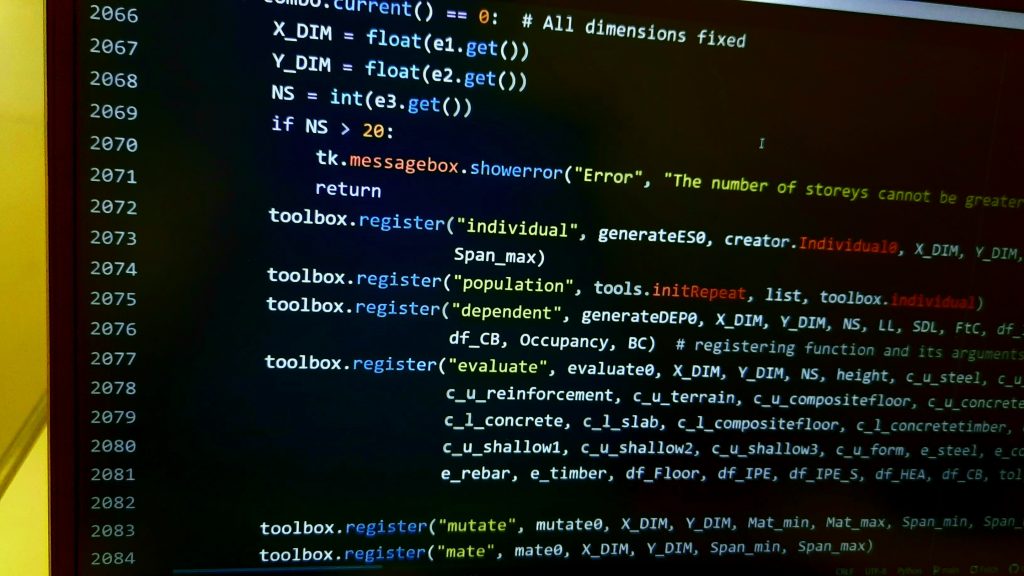

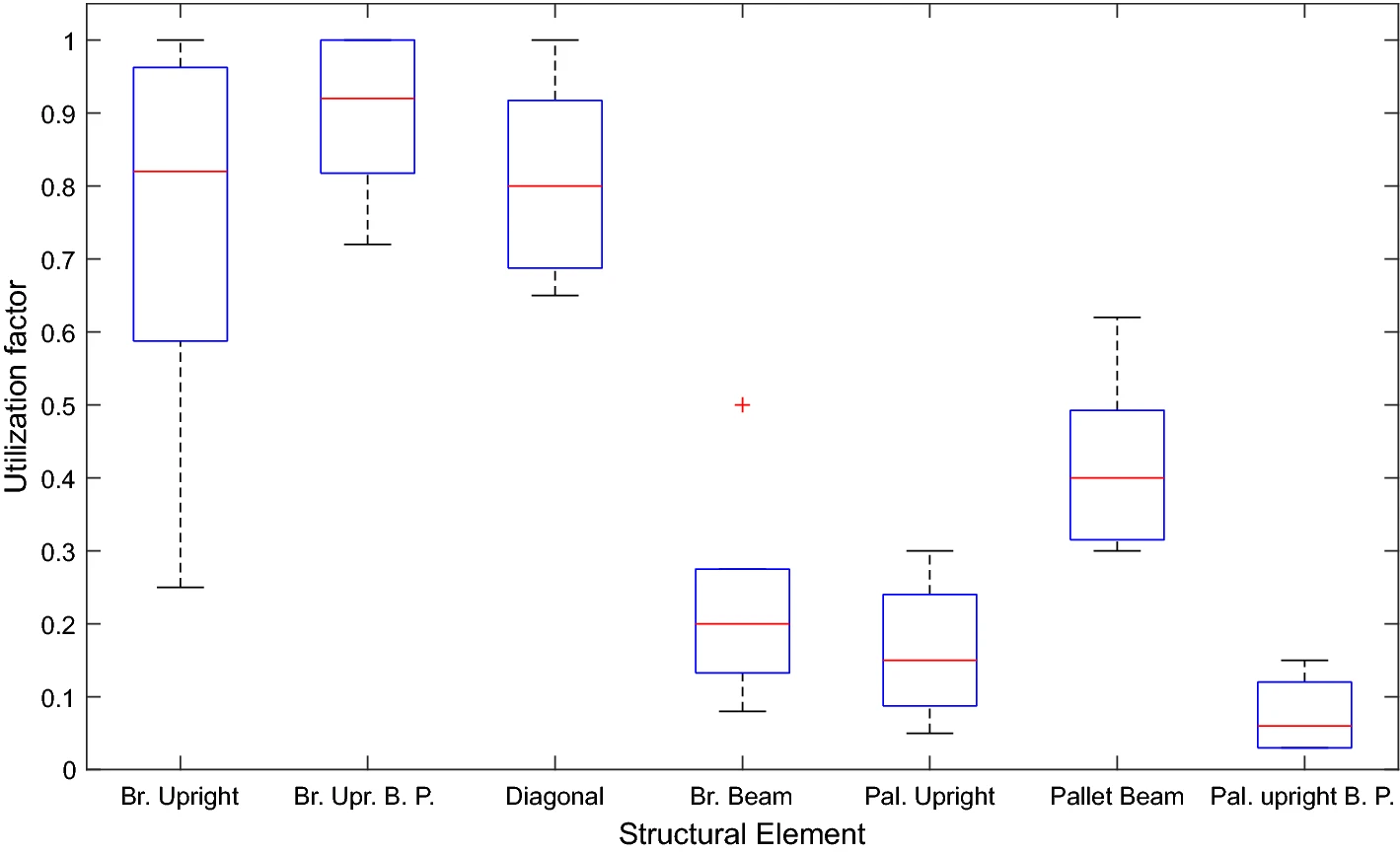

Kanyilmaz A., Tichell P.R.N., Loiacono D., A genetic algorithm tool for conceptual structural design with cost and embodied carbon optimization (2022) Engineering Applications of Artificial Intelligence, 112, art. no. 104711, https://doi.org/10.1016/j.engappai.2022.104711

Kanyilmaz A., Dang V., Kondratenko A., How does conceptual design impact the cost and carbon footprint of structures?, Structures, Volume 58, 2023, https://doi.org/10.1016/j.istruc.2023.105102.

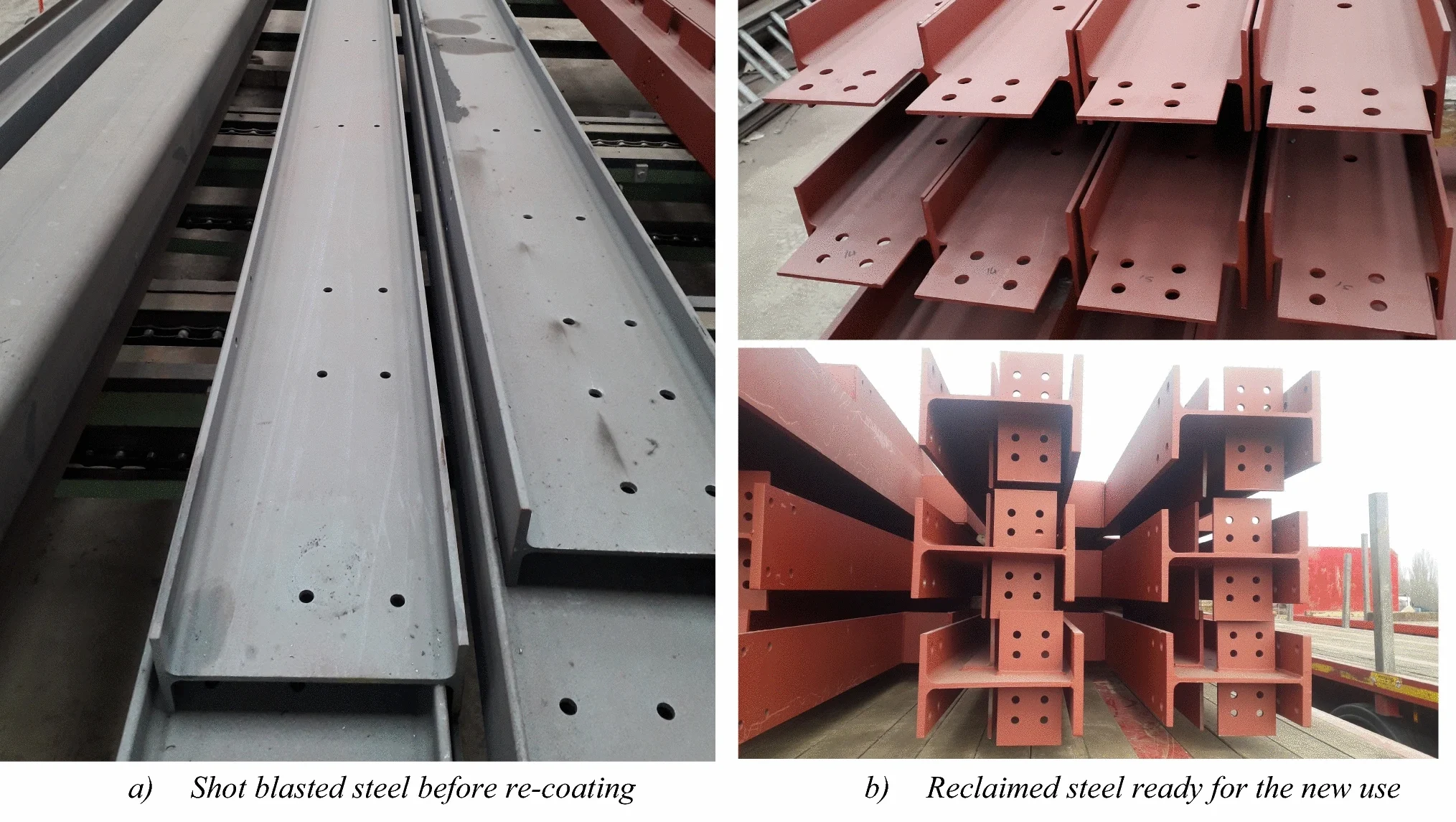

Kanyilmaz, A., Birhane, M., Fishwick, R., Castillo C.. Reuse of Steel in the Construction Industry: Challenges and Opportunities. Int J Steel Struct (2023). https://doi.org/10.1007/s13296-023-00778-4.

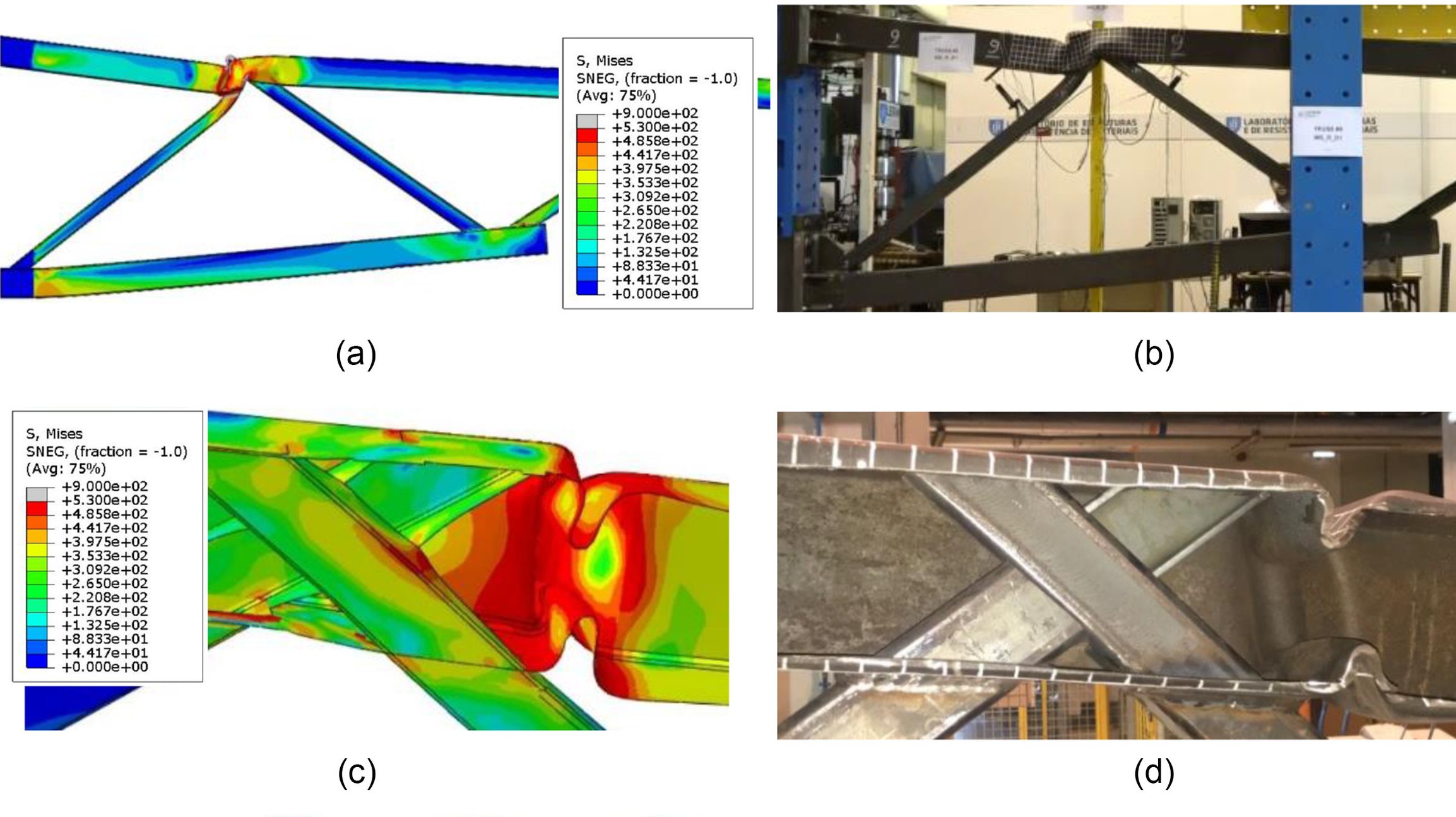

Menghini A., Kanyilmaz A., Calado L., Castiglioni C.A., Experimental Assessment of the Behavior of Tubular Truss Girder Joints Fabricated with Laser Cutting Technology (2023) Journal of Structural Engineering (United States), 149 (6), https://doi.org/10.1061/JSENDH.STENG-12019

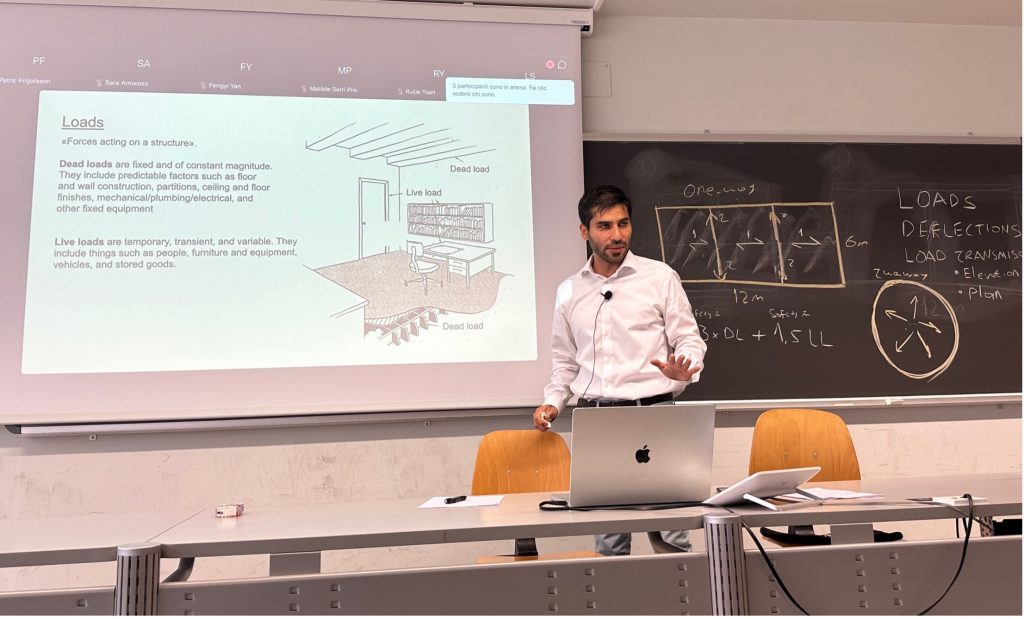

Teaching

He transfers his research experience to the civil engineering and architecture students (300/year) in terms of teaching, MSc and PhD thesis supervision. Moreover, Dr. Kanyilmaz provides industry-focused training courses aimed at mitigating embodied carbon within the Architecture, Engineering, and Construction (AEC) sector (you can contact him for a training request).

Dr. Kanyilmaz’s teaching, blending numerical simulations and hands-on experiments in class, lab, and online, echoes Socratic inquiry: “Can it be, Ischomachus, that asking questions is teaching? I am just beginning to see what is behind all your questions. You lead me on by means of things I know, point to things that resemble them, and persuade me that I know things that I thought I had no knowledge of.”

News